COURSE 3 OF THE EDA & SPC PROGRAM

Statistical Process Control & Capability Analysis

Providing industry professionals with self-paced, flexible, and practical training in data analysis.

Write your awesome label here.

About

What you get

Program

Certification

Meet the Trainer

-

Language: English

-

3 Courses, 9 lessons

-

1:1 mentoring session with the trainer.

-

Case studies across multiple industrial sectors, including Automotive, Moulds & Plastics, Pharmaceutical, Food, Logistics, Chemical, and more.

-

Excel tools with examples of how to plot histogram, normality plot, scatterplot, box plot and others on excel, how to get the statistic metrics, how to implement SPC with the control charts and capability studies, among many others.

Earn certificates for both the full learning program and each individual course by completing a final assessment. Certificates are issued once all questions are answered correctly. Along the way, each lesson includes a short knowledge check with unlimited attempts to help you practice what you’ve learned.

SIA certificates are proof of your expertise:

- Demonstrates mastery of practical, real-world engineering skills.

- Help you stand out to employers, clients, and project teams.

- Can be shared on LinkedIn, included in your CV, or used for professional development credits.

- Validate both technical competence and continuous learning.

Training accredited by DGERT.

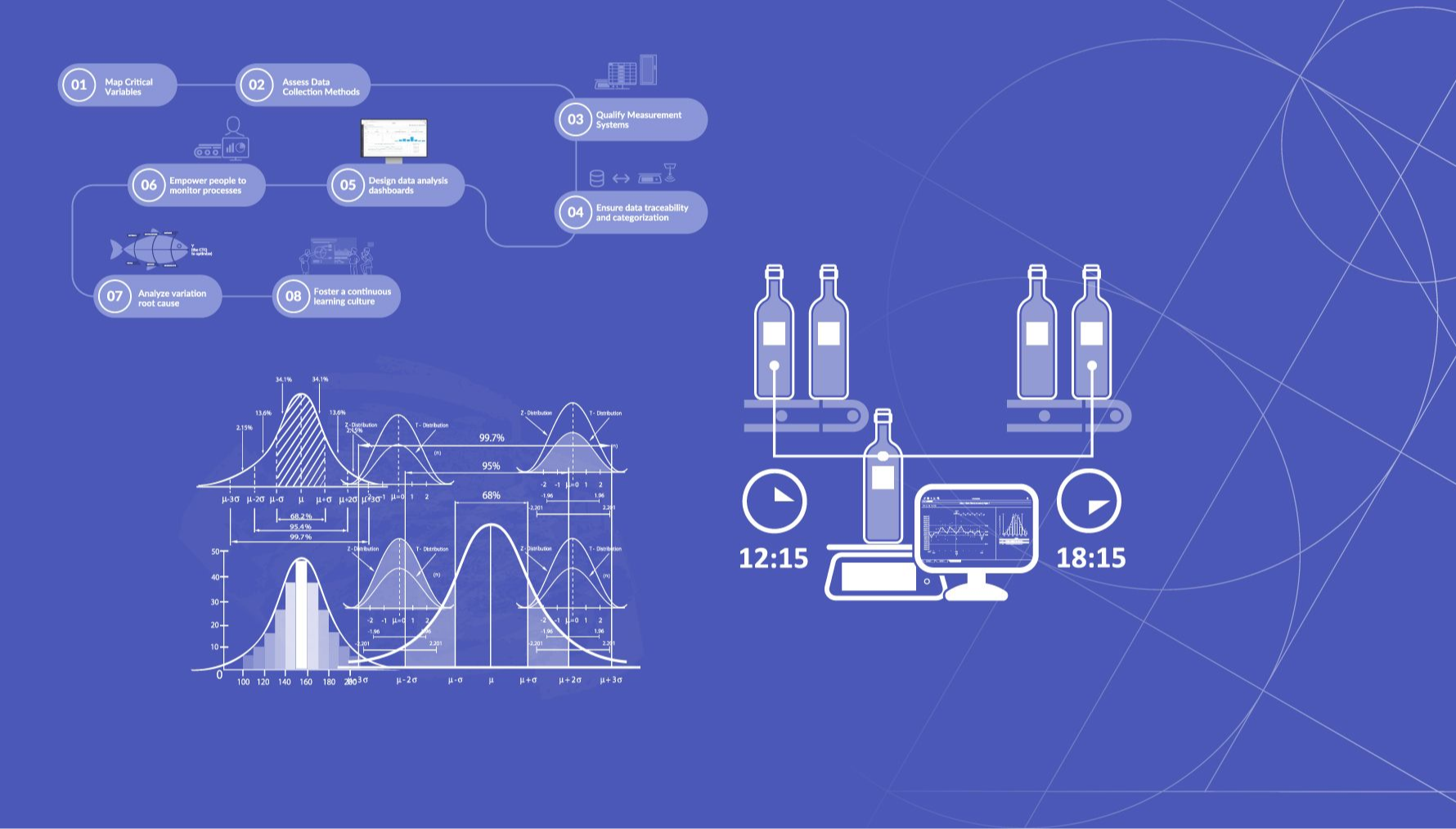

This course provides a practical, application-oriented journey through SPC—starting with foundational concepts, progressing through control charts for variables and categorical data, and culminating in capability studies and advanced principles of Statistical Quality Control.

You will learn not only how to apply SPC tools correctly but also why they matter: ensuring process stability, identifying sources of variation, improving production efficiency, and supporting continuous improvement initiatives across industries such as automotive, food & beverage, and pharmaceuticals.

By the end of the course, you will be equipped with the analytical skills and problem-solving mindset needed to interpret data confidently, respond to process signals, and contribute to robust quality systems.

Throughout the course, Excel will be the primary tool to support data organization, visualization, and analysis.

Learning Objectives

-

Apply SPC principles within quality systems to ensure process stability and improvement.

-

Use control charts for variables and attributes to monitor and interpret process performance.

-

Analyse process capability for normal and non-normal data against specifications.

-

Apply sampling, variation analysis, and statistical rules for accurate quality interpretation.

-

Leverage data analysis to construct charts, perform calculations, and interpret process performance metrics.

-

Identify and prioritise quality issues using FPY, Pareto, and capability indices.

-

Translate SPC insights into practical actions across industries for operational excellence.

-

High-Quality Video Lessons

Step-by-step training designed to be engaging, practical, and easy to follow, so you can learn at your own pace, anytime and anywhere.

-

Downloadable Templates

Access ready-to-use materials that turn learning into action: worksheets, checklists, scripts, and frameworks to implement immediately.

-

Quizzes

Reinforce your learning with interactive challenges that help you master each concept before moving on.

-

1:1 Sessions

Schedule a 1:1 session and receive dedicated support. Each session helps you apply what you’ve learned and move forward with total clarity.

-

Private Support & Messaging

Ask questions directly and get fast feedback so you’re never stuck or left figuring things out alone.

-

Discuss with others

Participate in our online forum, share thoughts and ideas, increase connection, get help with your studies.

Course contents

SIA is a global e-learning platform for industry

professionals advancing skills in data, quality,

and Industry 4.0.

Copyright © 2026

Social Media

Request a tailor-made onboarding kit

Request a custom proposal